Materials

Expert Material Guidance: Ensuring Fit, Function & Performance

Whether it be Fourslide/Multi-Slide tools or Progressive Dies, the principal objective in material selection is to ensure the proper function, performance and repeatability of the stamping or wire form while keeping unit cost competitive.

GEMCO offers you over 75 years of expertise with a vast range of materials including but not limited to:

- Low and high carbon steels

- 300 Series/400 Series/17-7 Stainless steels

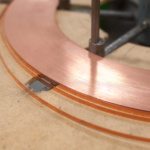

- Brass/Copper Alloys

- Phosphor bronze

- Beryllium copper

- Aluminum

- Tempered spring steel

- Music wire

- Pre-plated metals

- Thermostatic and clad metals

GEMCO partners with local vendors who provide post-processing such as heat treat, electrolytic, electroless and mechanical as well as precious metal plating, anodizing, painting and powder coating.

How can GEMCO help you today?

With over 75 years of experience, our customers continue to put their trust in GEMCO’s knowledge and responsive commitment to serving their unique needs. We’re prepared to earn your trust.